About Us

At WMC, we focus on improving rice production in Brunei by using innovative practices to deliver high-quality and sustainable rice products that meet the highest standards.

We are committed to supporting Brunei’s rice industry by working with the local agricultural community to promote growth and development.

Our goal is to contribute to the country’s food security and economic prosperity. Join us as we work towards a brighter future in rice production.

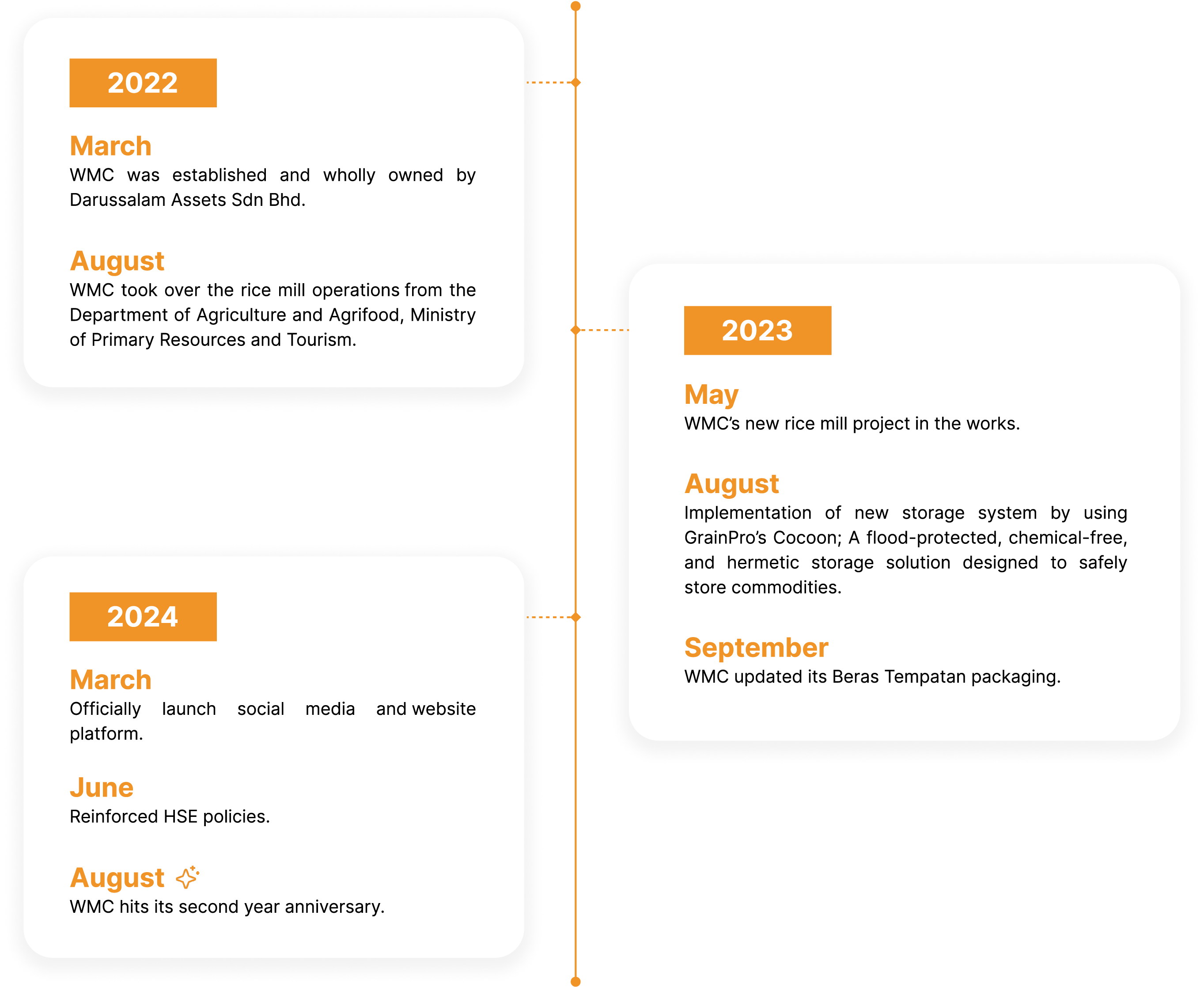

A brief history

The rice milling process involves several critical steps to transform harvested paddy rice into edible, polished rice.

Our Rice Milling Process

The rice milling process involves several critical steps to transform harvested paddy rice into edible, polished rice.

Paddy Cleaning Process

Rice Grinding & Separation Process

Pre-Cleaning (PETKUS)

Separation of paddy straw, immature paddy, rice husk and rice dust.

Destoner

Separation of stones and heavy impurities i.e. small pieces of metal chips.

Paddy Husker with Aspirator (Dehusking)

Separation of rice (paddy grain) and paddy husk.

Paddy Separator

Separation of brown rice and paddy & sorting of long, medium, and short grain rice.

Thickness Grader

Separation of brown rice & immature kernels according to thickness and width.

Rice Grading and Cleaning Process

Vertical Rice Whitener (Abrasive Whitening)

Rice whitening, to polish and remove the bran layer of rice grain.

Milling Polisher (Polisher)

Cleaning the surface of rice, enhancing the quality of finished products through the uniform removal of bran that can produce white & shiny rice.

Milling Polisher (Polisher)

Cleaning the surface of rice, enhancing the quality of finished products through the uniform removal of bran that can produce white & shiny rice.

Rotary Sifter

Separation of rice based on sizes.

Length Grader

Separation of one or two kinds of broken or shorter grains from whole grain by length.

Optical Sorter (Colour Sorter)

Separation of rice according to its quality (Discolored Rice).

Rice Packing Process

Semi-Automatic Packer (Packaging)

Rice packaging according to the weight of the sack.

Pre-Cleaning (PETKUS)

Separation of paddy straw, immature paddy, rice husk and rice dust.

Destoner

Separation of stones and heavy impurities i.e. small pieces of metal chips.

Paddy Husker with Aspirator (Dehusking)

Separation of rice (paddy grain) and paddy husk.

Paddy Separator

Separation of brown rice and paddy & sorting of long, medium, and short grain rice.

Thickness Grader

Separation of brown rice & immature kernels according to thickness and width.

Vertical Rice Whitener (Abrasive Whitening)

Rice whitening, to polish and remove the bran layer of rice grain.

Milling Polisher (Polisher)

Cleaning the surface of rice, enhancing the quality of finished products through the uniform removal of bran that can produce white & shiny rice.

Rotary Sifter

Separation of rice based on sizes.

Length Grader

Separation of one or two kinds of broken or shorter grains from whole grain by length.

Optical Sorter (Colour Sorter)

Separation of rice according to its quality (Discolored Rice).

Semi-Automatic Packer (Packaging)

Rice packaging according to the weight of the sack.

Our Responsibility

We have implemented comprehensive Health, Safety, and Environmental (HSE) policies to uphold WMC’s safety slogan:

“Safety Today For A Better Tomorrow”

Health and Safety Policy

Environmental Policy

Stop Work Policy